M3 submachine gun

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The M3 is an American .45 caliber submachine gun that uses the .45 ACP (11.43x23mm ACP) pistol cartridge. It entered US Army service on December 12 1942 as the United States Submachine Gun, Cal. .45, M3 and began to replace the .45 caliber Thompson series submachine guns: the M1928A1, M1 and M1A1 that were slowly being withdrawn from use. The weapon’s designer was G. Hyde, while F. Sampson – GMC’s Inland Division chief engineer – was responsible for preparing and organizing production. Even at the development stage, the weapon’s design was focused on simplified production, ease of use and the ability to convert the weapon to the 9x19mm Parabellum pistol cartridge. The weapon is commonly referred to as the "grease gun", owing to its similarity in appearance to the common mechanic's tool.

Contents |

Development

Initial prototypes carried the experimental designation T15, and after removing the fire safety selector - T20. In 1942 the submachine guns were subjected to a series of military evaluations, after which they received slightly extended stocks. This variant was then approved for production at GMC’s Guide Lamp Division facility. Close to 600,000 weapons were produced by the end of World War II, including approx. 25,000 models chambered for the 9x19mm Parabellum cartridge (which was achieved through swapping out the barrel, bolt and applying an adapter for use with the British 9 mm Sten submachine gun magazines), which were delivered to the OSS in 1944. The OSS also requested approx. 1000 .45-caliber submachine guns with an integral sound suppressor (designed by Bell Laboratories).

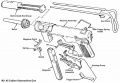

Design details

The M3 is an automatic only, blowback-operated firearm (the weapon’s bolt is assisted by two parallel wire-guide action springs) that fires from an open bolt. A spring extractor is located inside the bolt, while the fixed ejector – in the cocking handle assembly. The weapon is striker fired with the firing pin contained inside the bolt, the return springs act as the striker spring. The weapon is secured from accidental firing by closing the spring-loaded ejection port cover, which has a lug that engages notches in the bolt assembly’s surface, locking it in both its forward and rear positions. The firearm is fed from a double-column, single-feed 30-round detachable box magazine patterned after the British Sten gun.

The gun employs metal stamping and pressing, spot welding and welding. The bolt rides on two rods that are simultaneously the return spring guide rods. The weapon has a removable, rifled barrel. A conical flash hider (developed later) could be attached. The fixed iron sights consist of a rear aperture set for firing at 100 yards (approx. 91 m) and a blade foresight. The M3 is equipped with a folding (telescoping) metal wire stock, that can be removed and used to load rounds into the magazine. The stock also features threads at both ends used to attach a bore brush that creates a cleaning rod.

The M3 was originally designed as a disposable small arm, to be used and discarded once it became inoperative. However, in 1944, a shortage of new M3 weapons forced U.S. Army Ordnance workshops to fabricate pawl springs and other parts in order to keep existing weapons operational.[1][2]

Variants

In December 1944 a modernized version of the M3 was introduced into service known as the M3A1, with all parts except the bolt, housing assembly and receiver interchangeable with those of the M3. The M3A1 had several modifications. The most significant was the removal of the troublesome spring-powered, crank-type retracting (cocking) lever mechanism, replaced by a simple recessed cocking slot machined into the bolt to allow it to be cocked with the user’s finger. The ejection port and ejection port cover were also lengthened to allow the bolt to be drawn back far enough to be engaged by the sear, a magazine release button cover was added, and a magazine loading bracket was welded to the wire stock. The bolt latch was changed, the barrel bushing received two flat cuts that assist in barrel removal by use of the stock as a wrench, a larger oiler was used and a spare lubricant mount was removed (located at the left side of the cocking lever assembly), replaced with an oiler installed inside the pistol grip. The M3 magazine design was retained; in an effort to improve reliability, plastic caps were issued to seal loaded magazines from dirt and debris until needed for use.[3]

The modifications resulted in a reduced weight and improved reliability; these changes also improved maintenance and field stripping (i.e. to remove the bolt and recoil assembly the user simply has to unscrew the barrel; in the original M3 it was necessary to first remove the trigger guard, then detach the cocking crank assembly from the receiver housing). Many M3 weapons were converted to M3A1 standard: during the conversion, armorers frequently removed the M3 cocking handle, leaving the rest of the now-redundant cocking mechanism inside the subframe.[4] Overall, the M3A1 was seen by most soldiers and Ordnance technicians as an improvement over the M3. However, complaints of accidental discharge continued to occur even as late as the Korean War.[5] These incidents were sometimes caused by dropping the weapon on a hard surface with a impact sufficient to knock open the ejection port cover and cause the bolt to slam closed, picking up a cartridge from the magazine.[6]

In 1945, the Guide Lamp factory manufactured close to 15,500 M3A1 submachine guns. During the Korean War, another 33,000 units were built at the Ithaca Gun Co.

The M3 and M3A1 were mostly withdrawn from US service in 1957; however they continued to be used until the mid 1990s by armored vehicle crews and truck drivers. For example, during the Gulf War of 1991, drivers of the 19th Engineer Battalion, attached to the 1st Armored Division, were deployed with the M3A1.

In 1955 production was initiated at the Argentine FMAP plant in Rosario of the PAM1 submachine gun (an M3 chambered in the 9x19mm Parabellum pistol caliber), and later the PAM2 (PAM1 with a grip safety).

Users

- Argentina

- China - Copies made as the Type 36[7] and used in the Korean War by Chinese soldiers[8].

- Ecuador

- Japan - Had armed the JSDF for a short time before adopting the Minebea PM-9[9][10][11].

- Philippines - Had their M3 submachine guns released from reserve stockpiles by the Philippine Navy for the Philippine Marine Corps's special forces due to budget reasons[12]. Modifications done on the refurbished weapons include integral silencer and a picatinny railing[13]. The weapon had been tested with a prototype on May 2004[12].

- South Korea - Replaced by K1A

- South Vietnam

- United States

See also

- MCEM 1 submachine gun, similar weapon with a grip magazine.

Resources

The Gun Owners' Resource online library has the following documents available for free download for this firearm:

- M3 & M3A1 Technical Manual - document TM9-1005-229-35, Department of the Army, Washington DC, September 1969 (.PDF file, 54 pgs, 980 KB)

- M3 & M3A1 Field Manual - document FM 23-41, Department of the Army, Washington DC, 28 June 1974 (82 pgs, 1.7 MB)

The following diagrams are also available for reference:

References

- ↑ Dunlap, Roy, Ordance Went Up Front, Samworth Press (1948), p. 300

- ↑ 2nd Ranger Battalion, World War II Living History Group, M3A1 Submachine Gun. Retrieved on September 19, 2008.

- ↑ Hogg, Ian V. and Weeks, John, Military Small Arms of the 20th Century, 6th ed. DBI Books ISBN 0873491203, p.246

- ↑ Hackworth, David H. and Sherman, Julie, About Face: The Odyssey of an American Warrior, New York: Simon and Schuster (1989) ISBN: 0671526928

- ↑ Hackworth, David H. and Sherman, Julie, About Face: The Odyssey of an American Warrior, New York: Simon and Schuster (1989) ISBN: 0671526928

- ↑ Hackworth, David H. and Sherman, Julie, About Face: The Odyssey of an American Warrior, New York: Simon and Schuster (1989) ISBN: 0671526928

- ↑ Chinese copy of US M3A1 Grease Gun

- ↑ M3A1 Grease Gun

- ↑ 演習場で大活躍!自衛隊の火器(本物)

- ↑ http://rightwing.sakura.ne.jp/equipment/jgsdf/infantry/9mmmpjgsdf/9mmmpjgsdf.html 9mm機関けん銃]

- ↑ 11.4mm短機関銃M3A1

- ↑ 12.0 12.1 M3 Grease Guns Re-issued

- ↑ New Sights for a Revived Workhorse: The M3 SpecOps Generation 2

Bibliography

- Dunlap, Roy F., Ordnance Went Up Front, Samworth Press, 1948.

- Nelson, Thomas B. The World's Submachine Guns, TBN Enterprises, 1963.

- Weeks, John, WWII Small Arms, Galahad Books, 1980.

- Iannamico, Frank A., The U.S. M3-3A1 Submachine Gun, Moose Lake Publishing, 1999.

- Iannamico, Frank A., United States Submachine Guns, Moose Lake Publishing, 2004.