Internal ballistics

Internal ballistics, a subfield of ballistics, is the study of a projectile's behavior from the time its propellant's igniter is initiated until it exits the gun barrel. The study of internal ballistics is important to designers and users of firearms of all types, from small-bore Olympic rifles and pistols, to high-tech artillery.

Contents |

Priming methods

The first step to firing a firearm of any sort is igniting the propellant. The earliest firearms were cannons, which were simple closed tubes. There was a small aperture, the "touchhole", drilled in the closed end of the tube, leading down to the main powder charge. This hole was filled with finely ground powder, which was then ignited with a hot ember or torch. With the advent of hand-held firearms, this became an undesirable way of firing a gun. Holding a burning stick, while trying to carefully pour a charge of black powder down a barrel, is dangerous, and trying to hold the gun with one hand while simultaneously aiming at the target and looking for the touchhole was not conducive to any degree of accuracy.

External priming

Matchlock

- Main article: Matchlock

The first attempt to make the process of firing a small arm easier was the "matchlock". The matchlock incorporated a "lock" (so called, because of its resemblance to door locks of the day) that was actuated by a trigger. The lock was a simple lever which pivoted, when pulled, and lowered the match down to the touchhole. The match was a slow burning fuse made of plant fibers that were soaked in a solution of nitrates, charcoal, and sulfur, and dried. This was ignited before the gun might be needed, and it would slowly burn, keeping a hot ember at the burning end. After the gun was loaded, and the touchhole primed with powder, the burning tip of the match was positioned, so that the lock would bring it into contact with the touchhole. To fire the gun, it was aimed, and the trigger pulled. This brought the match down to the touchhole, igniting the powder. The slow burning match could be kept going, with careful attention, for long periods of time, and the use of the lock mechanism made accurate fire (within the limits of the gun) possible.

Wheel-lock

- Main article: Wheel-Lock

The next revolution in ignition technology was the "wheel-lock". It used a spring-loaded, serrated steel wheel which rubbed against a piece of iron pyrite. There was a key which was used to wind the wheel, and put the spring under tension. Once tensioned, the wheel was held in place by a trigger. When the trigger was pulled, the serrated edge of the steel rubbed against the pyrite, generating sparks. These sparks were directed into a pan, called the "flashpan", filled with loose powder which lead into the touchhole. The flashpan was usually covered by a spring-loaded cover that would slide out of the way when the trigger was pulled, exposing the powder to the sparks. The wheel-lock was a major innovation — since it did not rely on burning material as a source of heat, it could be loaded, and kept loaded for extended periods of time. The covered flashpan also gave the gun some ability to withstand bad weather. Wind, rain, and wet weather would render a matchlock useless, but a wheel-lock that was loaded, and waterproofed with a bit of grease around the flashpan, could be fired under most conditions.

Flintlock

- Main article: Flintlock

The wheel-lock enjoyed only a brief period of popularity before being superseded by a simpler, more robust design. The "flintlock", like the wheel-lock, used a flashpan and a spark to ignite the powder. As the name implies, the flintlock used flint, rather than iron pyrite. The flint was held in a spring-loaded arm, called the "cock". The cock rotated through about a 90 degree arc, and was held in the tensioned, or "cocked" position by a trigger. Usually, flintlocks would lock the cock in two positions. The "half-cock" position held the cock halfway back, and used a deep notch, so that pulling the trigger would not release the cock. This was a safety position, used when loading, and when storing or carrying a loaded flintlock. The "full-cock" position held the cock all the way back, and was the position from which the gun was fired. The "frizzen" was the other half of the flintlock ignition system. It served as both a flashpan cover, and a steel striking surface for the flint. The frizzen was hinged, and spring-loaded, so that it would lock in the open or closed position. When closed, the striking surface was positioned so that the flint would strike at the proper angle to generate a spark. The striking flint would also open the frizzen, exposing the flashpan to the spark. The flintlock mechanism was simpler, and stronger than the wheel-lock, and the flint and steel provided a good, reliable source of ignition. The flintlock remained in military service for over 200 years, and flintlocks are still made today for historical re-enactments, and for hunters who enjoy the additional challenge that the flintlock provides.

Caplock

- Main article: Caplock

The next major leap in ignition technology was the invention of the chemical primer, or "cap", and the mechanism which used it, called the "caplock". The caplock appeared just before the American Civil War, and was quickly adopted by both sides as it was even simpler and more reliable than the flintlock. The main reason the caplock was so quickly adopted was its similarity to the flintlock. The flashpan and frizzen were removed, and replaced by a "nipple" which the cap fit onto. The cock was replaced by a "hammer", which also had half-cock and full-cock positions for the same reasons. When fired, the hammer would hit the cap, crushing it onto the nipple. The percussion cap was a thin metal cup that contained a small quantity of pressure-sensitive explosive. When crushed, the explosive would detonate, sending a stream of hot gas down a hole in the nipple, and into the touchhole of the gun. In the process of firing, the cap generally split open, and would fall off, when the hammer was moved to half-cock position for loading. The caplock system worked well, and is still the preferred method of ignition for hunters and recreational shooters who use muzzle-loading arms.

Internal priming

Chemical primers, advanced metallurgy and manufacturing techniques all came together in the 1800s to create an entirely new class of firearm — the cartridge arm. Flintlock and caplock shooters had long carried their ammunition in paper cartridges, which served to hold a measured charge of powder, and a bullet in one convenient package (the paper also served to seal the bullet in the bore). Still, the source of ignition was separate. With the advent of chemical primers, it was not long before all sorts of systems were invented, with a multitude of different ways of combining bullet, powder, and primer into one package which could quickly be loaded from the breech of the firearm. The three systems which have survived the test of time are the rimfire, the Berdan primer, and the Boxer primer.

Rimfire

- Main article: Rimfire

Rimfire cartridges use a thin brass case with a bulge, or rim, around the back end. This rim is filled, during manufacture, with an impact-sensitive primer. In the wet state, the primer is stable; a pellet of wet primer is placed in the shell, and simply spun out to the full extremes of the rim. (For more on the exact process and one set of chemical compounds that have been used successfully, see see U.S. Patent 1,880,235 , a 1932 Remington Arms patent by James E. Burns.) In the dry state, the primer within the rim becomes impact-sensitive. When the rim is then crushed by the hammer or firing pin, the primer detonates and ignites the powder charge. Rimfire cartridges are single-use: After firing, they cannot practically be reloaded. Also, since the rim must be thin enough to be easily crushed, the peak pressure generated in the case is limited by the strength of this thin rim. Rimfire cartridges were previously available in calibers up to .44, but all except the small .22 caliber rounds died out. The .22 Long Rifle, also fired in pistols, is the most popular recreational caliber, because it is inexpensive, quiet, and has very low recoil. The most inexpensive brands can be bought for less than US$0.02 per round in boxes of 500, and even Olympic class ammunition is around US$0.20 per round.

While the rimfire priming method is limited due to the thin cases required, it has enjoyed a few resurgences in the recent past. First was Winchester's .22 Magnum Rimfire, or .22 WMR, in the 1950s, followed in 1970 by Remington's short lived 5 mm Magnum Rimfire, based on Winchester's magnum case. In 2002 Hornady introduced a new .17 caliber cartridge based on the .22 WMR, the .17 HMR. The .17 HMR is essentially a .22 WMR cartridge necked down to accept a .17 caliber bullet, and is used as a flat-shooting, light duty varmint round. The .17 HMR was followed a year later by the Hornady's .17 Mach 2, or .17 HM2, which is based on a slightly lengthened and necked down .22 Long Rifle cartridge. Both of the .17 caliber rimfires have had widespread support from firearms makers, and while the high-tech, high velocity .17 caliber jacketed bullets make the .17 Rimfire cartridges quite a bit more expensive than the .22 caliber versions, they are still far less expensive than comparable centerfire cartridges.

Pinfire

- Main article: Pinfire

A pinfire firearm cartridge is an obsolete type of brass cartridge in which the priming compound is ignited by striking a small pin which protrudes radially from just above the base of the cartridge. Invented by Casimir Lefaucheaux in 1828 but not patented until 1835, it was one of the earliest practical designs of a metallic cartridge.

Peripheral primer

- Main article: Steyr ACR

This unique system, much like a refined combination of the pinfire and rimfire, uses a firing pin that strikes a ring of priming compound in the center of the cartridge as described in in U.S. Patent 4,848,237 . Despite being successful, only experimental batches of the cartridge were made. The primary advantage is that it is struck from the side. This allows the operating system of the firearm to be moved forward making for a more compact system.

Berdan primer

Berdan primers are named after their American inventor, Hiram Berdan of New York who invented his first variation of the Berdan primer and patented it on March 20, 1866, in U.S. Patent 53,388 . A small copper cylinder formed the shell of the cartridge, and the primer cap was pressed into the outside end of the cartridge opposite the bullet from the outside. In the end of the cartridge beneath the primer cap was a single vent-hole, as well as a small "teat-like projection" or point fashioned from the case, later to be known as an anvil, upon which to provide a hard surface behind the primer cap, such that the firing pin would have a hard surface against which to crush the primer and ignite the propellant. This system worked well, allowing the option of installing a cap just before use of the propellant-loaded cartridge, as well as permitting re-loading the cartridge for re-use. Difficulties arose in practice because pressing in the cap from the outside tended to cause a swelling of the copper cartridge shell, preventing the reliable seating of the cartridge in the chamber of the firearm. Berdan's solution was to change to brass shells, and to further modify the process of installing the primer cap into the cartridge, as noted in his second Berdan Primer patent of September 29, 1869, in U.S. Patent 82,587 . Berdan primers have remained essentially the same functionally to the present day.

Berdan primers are similar to the caps used in the caplock system, being small metal cups with pressure-sensitive explosive in them. Modern Berdan primers are pressed into the primer "pocket" of a Berdan-type cartridge case, where they fit slightly below flush with the base of the case. Inside the primer pocket is a small bump, the "anvil", that rests against the center of the cup, and two small holes that allow flash from the primer to reach the interior of the case. Berdan cases are reusable, although the process is rather involved. The used primer must be removed, usually by hydraulic pressure, or a lever that pulls the primer out of the bottom. A new primer is carefully seated against the anvil, and then gunpowder and a bullet are added. Berdan priming is used by nearly all militaries and most civilian manufacturers, with the exception of those in the United States, to discourage reloading of ammunition because the Berdan primer is difficult to remove from the case without damaging the anvil.

Boxer primers

Meanwhile, Edward M. Boxer, of the Royal Arsenal, Woolwich, England was working on a similar primer cap design for cartridges, patenting it in England on October 13, 1866, and subsequently received a U.S. patent for his design on June 29, 1869, in U.S. Patent 91,818.

Boxer primers are similar to Berdan primers with one major change — the location of the anvil. In a Boxer primer, the anvil is a separate piece that sits in the primer cup. Because of this, the primer pocket has the flash-hole centered. This makes little or no difference to the performance of the round, but it makes fired primers vastly easier to remove for re-loading. A thin metal rod is pushed through the mouth of the case, and it pushes the primer out. A new primer, anvil included, is then pressed into the case. Since the primer and anvil are sold as one part, the anvil depth must be correct for the primer that is being inserted, so that the primer does not ignite during loading (although priming is done as the first step, before the powder is added). This is the main reason why Boxer priming is still popular in the USA, as there are a large number of shooters who reload their ammunition.

Boxer-primed ammunition is slightly more complex to manufacture, since the primer is in two parts, but the slight increase in initial cost is often more than equalized by the decreased cost of firing reloaded rounds, at least for users intending to reload rounds. However, in much military-surplus ammunition, Berdan-primed ammunition is often found to be more common, having been both cheaper and faster to produce for filling very large orders intended for military use. Military surplus Berdan-primed ammunition is also often corrosive or slightly corrosive, whereas Boxer-primed ammunition is often noncorrosive, although assuming corrosive or noncorrosive characteristics on the basis of whether Berdan or Boxer primed is never foolproof. Berdan and Boxer are both considered "centerfire" and are interchangeable; the same firearm can fire both Berdan- and Boxer-primed rounds.

Primer sizes

Primers come in different sizes, based on the application. The types/sizes of primers are:

- For both pistol and rifle: Small and Large, in Standard and Magnum versions.

- .209 primers for shotgun shells and modern inline muzzleloaders.

- .50 BMG primers, used for the .50 Browning Machine Gun cartridge and derivatives

- Specialty primers for extremely small centerfire cases, or for large cannon cartridges

Examples of uses:

- .38 Special, small pistol standard

- .357 Magnum, small pistol magnum

- .45 ACP, large pistol standard

- .223 Remington, small rifle standard

- .308 Winchester, large rifle standard

- .270 WSM, large rifle magnum

The primer size is based on the primer pocket of the cartridge, with standard types available in large or small diameters. The primer explosive charge is based on the amount of ignition required by the cartridge design; a standard primer would be used for smaller charges or faster burning powders, while a magnum primer would be used for larger charges or slower burning powders. The magnum primers increase the impulse power of powder, by supplying a hotter and stronger flame. The main differences between pistol and rifle primers are the amount of force required to ignite the primer and the amount of flame produced. The primary difference between pistol and rifle primers is the thickness of the primer's case; pistol primers are thinner, softer, and easier to ignite, while rifle primers are thicker, stronger, and require a harder impact from the firing pin. Despite the names pistol and rifle, the primer used depends on the cartridge, not the firearm; high pressure pistol cartridges like the .221 Fireball and .454 Casull use rifle primers, while low pressure cartridges like traditional revolver cartridges commonly used in lever action rifles would still be loaded with pistol primers.

Electrical

A very small but growing number of civilian arms are switching to electrical triggers. These use an electrical charge, powered by a battery, to detonate the primer and decrease the time between pulling the trigger and ignition of the charge. The control circuitry attendant with electrical triggers also offers opportunities for biometric safety locks, remote trigger mountings, and tele-operation of the weapon.

Propellants

Black powder

- Main article: Gunpowder

Gunpowder (Black powder) is a pressed mechanical mixture of sulfur, charcoal, and potassium nitrate or sodium nitrate. It can be produced in a range of grain sizes. The size and shape of the grains can increase or decrease the relative surface area, and change the burn rate significantly. Unlike smokeless propellants, it acts more like an explosive since its burn rate is not affected by pressure. However, it is a very poor explosive because it has a very slow decomposition rate, and therefore a very low brisance.

Nitrocellulose (single base propellants)

- Main article: Smokeless powder

Nitrocellulose is formed by the action of nitric acid on cellulose fibers. It is a highly combustible fibrous material that deflagrates rapidly, when heat is applied. It also burns very cleanly, burning almost entirely to gaseous components at high temperatures. The burning rate of nitrocellulose is dependent upon the pressure — a pile of uncontained nitrocellulose will burn slowly, with a high, bright flame, but when placed in a high strength, sealed container, the same material will burn very quickly, bursting the container.

Gelatinised nitrocellulose is a plastic, it can be formed into many shapes of gun propellants, such as cylinders, tubes, balls, and flakes. The size and shape of the propellant grains can increase or decrease the relative surface area, and change the burn rate significantly. Additives and coatings can be added to the propellant to further modify the burn rate. Normally, very fast powders are used for low-velocity pistols and shotguns, medium-rate powders for magnum pistols and light rifle rounds, and slow powders for large-bore heavy rifle rounds.[1] These are known as Single-base propellants.

Double base propellants

- Main articles: Ballistite, Cordite, Smokeless powder

To further increase the energy of smokeless powder, nitroglycerin can be added in amounts up to 50%. These powders are called "double base powders", and they have the same basic physical properties as single base powders. The nitrocellulose serves to desensitize the highly unstable nitroglycerin; and the nitroglycerin gelatinises the nitrocellulose and greatly increases the energy density of the resulting powder. Double base powders burn faster than single base powders of the same shape, and in general, the higher the nitroglycerin content of a powder, the faster the burn rate.

In artillery, Ballistite or Cordite has been used in the form of rods, tubes, slotted-tube or multi-tubular; the geometry being chosen to provide the required burning characteristics.

Solid propellants (caseless ammunition)

A recent topic of research has been in the realm of "caseless ammunition". In a caseless cartridge, the propellant is cast as a single solid grain, with the priming compound placed in a hollow at the base, and the bullet glued to the front. Since the single propellant grain is so large (most smokeless powders have grain sizes around 1 mm, a caseless grain will be perhaps 7 mm diameter and 15 mm long), the relative burn rate must be much higher. To reach this rate of burning, caseless propellants often use moderated explosives, such as RDX.

While there is at least one experimental military rifle (the H&K G11), and one commercial rifle (the Voere VEC-91), that use caseless rounds, they are not having much success. The caseless ammunition is by necessity, not reloadable (a major disadvantage in civilian markets, where reloading is common), and the exposed propellant makes the rounds less rugged. Also, the case in a standard cartridge serves as a seal, keeping gas from escaping the breech. Caseless arms must use a more complex self-sealing breech, which increases the design and manufacturing complexity. Another problem, common to all auto-loading arms but particularly problematic for those firing caseless rounds, is the problem of rounds "cooking off". This is caused by residual heat from the chamber heating the round in the chamber to the point where it ignites, causing an unintentional discharge.

Belt-fed machine guns, designed for high volumes of fire, are designed to fire from an open bolt, which means that the round is not chambered until the trigger is pulled, and so there is no chance for the round to cook off before the operator is ready. Open-bolt designs are generally undesirable for anything but belt-fed machine guns and pistol-sized submachine guns. The reason is that the mass of the bolt, moving forward, causes the gun to lurch in reaction, which significantly reduces the accuracy of the gun. Since one of the motivating factors for the use of caseless rounds is to increase the rate of fire to the degree that several shots can be fired to the same point of aim, anything that reduces the accuracy of those first shots would be counterproductive. Cased ammunition serves as a heat sink to both carry heat away from the chamber after firing, and to cool the chamber when chambered, reducing the risk of cook off.

Propellant charge

Load density and consistency

Load density is the percentage of the space in the cartridge case that is filled with powder. In general, loads close to 100% density (or even loads where seating the bullet in the case, compresses the powder) ignite and burn more consistently than lower density loads. In cartridges that survived from the black powder cartridge era (examples being .45 Colt, .45-70 Government), the case is much larger than needed to hold the maximum charge of high-density smokeless powder. This allows the powder to shift in the case, piling up near the front, or near the back of the case. This can cause significant variations in burning rate, as powder near the rear of the case will ignite rapidly, but powder near the front of the case will ignite slower. This change has less impact with fast powders. As such, high-capacity, low-density cartridges generally deliver best accuracy with the fastest appropriate powder, although this keeps the total energy low, due to the sharp high pressure peak.

Magnum pistol cartridges reverse this power/accuracy trade off, by using lower density powders that give high load density, and a broad pressure curve. The downside is the increased recoil and muzzle blast from the high powder mass, and high muzzle pressure. The advantage is that the magnum pistol rounds generate accuracy that is comparable to a good hunting rifle, and energy sufficient to take medium game at ranges out to 100 yards (100 m) and beyond.

Most rifle cartridges have a high load density with the appropriate powders. Rifle cartridges tend to be bottlenecked, with a wide base narrowing down to a smaller diameter, to hold a light, high-velocity bullet. These cases are designed to hold a large charge of low-density powder, for an even broader pressure curve than a magnum pistol cartridge. These cases require the use of a long rifle barrel to extract their full efficiency, although they are also chambered in rifle-like pistols (single shot or bolt action) with barrels of 10 to 15 inches (25 to 38 cm).

One unusual phenomenon occurs when high density powders are used in large capacity rifle cases. Small charges of powder, unless held tightly near the rear of the case by wadding, can apparently detonate when ignited. The mechanism of this phenomenon is not well-known, and generally it is not encountered, except when loading very low velocity subsonic rounds for rifles. These rounds generally have velocities of under 500 ft/s (195 m/s), and are used for indoor shooting, or pest control, where the power and muzzle blast of a full power round is not needed or desired.

This detonation problem seems strange because we intuitively think that less propellant will produce less power. A possible explanation for it lies with the relationship between the temperature, pressure and volume of a gas and the fact that the rate at which the propellant burns increases very rapidly with increase of temperature. Temperature is proportional to pressure/volume. So as pressure increases the temperature increases proportionally but as volume increases the temperature falls proportionally to the inverse of the volume. When a normal cartridge is fired under normal circumstances the bullet moving down the barrel increases the volume containing the hot high pressure gas. That reduces its temperature and holds down the burn rate which is the generator of pressure. This acts as a kind of control as the propellant keeps burning down two thirds or more of the barrel. With a low, non packed charge, the explosion of the primer swirls the propellant particles around in its hot gasses and ignites all of them simultaneously rather than progressively. Because the mass of propellant is so low, the same heat input from the primer heats them to a higher initial temperature and so their first stage burn is at a higher rate. Because there is only a small amount of propellant the pressure is not at first high enough to start the bullet moving quickly and so there is time for the propellant to burn completely at high temperature and pressure while it is still in a small space. It is easy to see that this could create the circumstances for detonation as the increase of volume fights to control the temperature and burn rate.

Chamber

Straight vs bottleneck

Straight walled cases were the standard from the beginnings of cartridge arms. With the low burning speed of black powder, the best efficiency was achieved with large, heavy bullets, so the bullet was the largest practical diameter. The large diameter allowed a short, stable bullet with high weight, and the maximum practical bore volume to extract the most energy possible in a given length barrel. There were a few cartridges that had long, shallow tapers, but these were generally an attempt to use an existing cartridge to fire a smaller bullet with a higher velocity and lower recoil. With the advent of smokeless powders, it was possible to generate far higher velocities by using a slow smokeless powder in a large volume case, pushing a small, light bullet. The odd, highly tapered 8 mm Lebel, made by necking down an older 11 mm black powder cartridge, was introduced in 1886, and it was soon followed by the 7.92 x 57 mm Mauser and 7 x 57 mm Mauser military rounds, and the commercial .30-30 Winchester, all of which were new designs built to use smokeless powder. All of these have a distinct shoulder that closely resembles modern cartridges, and with the exception of the odd, highly tapered 8 mm Lebel, they are still chambered in modern firearms even though the cartridges are over a century old.

Aspect ratio and consistency

When selecting a rifle cartridge for maximum accuracy, a short, fat cartridge with very little case taper will generally yield higher efficiency and more consistent velocity than a long, thin cartridge with a lot of case taper (part of the reason for a bottle-necked design). Given current trends towards shorter and fatter cases, such as the new Winchester Super Short Magnum cartridges, it appears the ideal might be a case approaching spherical inside.[2] Target and varmint hunting rounds require the greatest accuracy, so their cases tend to be short, fat, and nearly untapered with sharp shoulders on the case. Short, fat cases also allow short-action weapons to be made lighter and stronger for the same level of performance. The trade-off for this performance is fat rounds which take up more space in a magazine, sharp shoulders that do not feed as easily out of a magazine, and less reliable extraction of the spent round. For these reasons, when reliable feeding is more important than accuracy, such as with military rifles, longer cases with shallower shoulder angles are favored. There has been a long-term trend however, even among military weapons, towards shorter, fatter cases. The current 7.62 x 51 mm NATO case replacing the longer .30-06 Springfield is a good example, as is the new 6.5 Grendel cartridge designed to increase the performance of the AR-15 family of rifles and carbines.

Friction and inertia

Static friction and ignition

Since the burning rate of smokeless powder varies directly with the pressure, the initial pressure buildup has a significant effect on the final velocity, especially in cartridges with fast powders. The friction, holding the bullet in the case, determines how soon after ignition the bullet moves, and since the motion of the bullet increases the volume and drops the pressure, a difference in friction can change the slope of the pressure curve. In general, a tight fit is desired, to the extent of crimping the bullet into the case. In straight-walled rimless cases, such as the .45 ACP, an aggressive crimp is not possible, since the case is held in the chamber by the mouth of the case, but sizing the case to allow a tight interference fit with the bullet, can give the desired result.

Kinetic friction

The bullet must tightly fit the bore to seal the high pressure of the burning gun powder. This tight fit generates a large quantity of friction. The friction of the bullet in the bore does have a slight impact on the final velocity, but that is generally not much of a concern. Of greater concern is the heat that is generated, due to the friction. At velocities of about 1000 ft/s (390 m/s), lead begins to melt, and deposit in the bore. This lead build-up constricts the bore, increasing the pressure and decreasing the accuracy of subsequent rounds, and is difficult to scrub out, without damaging the bore. Rounds, used at velocities up to 1500 ft/s (585 m/s), can use wax lubricants on the bullet to reduce lead build-up. At velocities over 1500 ft/s (585 m/s), nearly all bullets are jacketed in copper, or a similar alloy that is soft enough not to wear on the barrel, but melts at a high enough temperature to reduce build-up in the bore. Copper build-up does begin to occur in rounds that exceed 2500 ft/s (975 m/s), and a common solution is to impregnate the surface of the bullet with molybdenum disulfide lubricant. This reduces copper build-up in the bore, and results in better long-term accuracy.

The role of inertia

In the first few inches (centimeters) of travel down the bore, the bullet reaches a significant percentage of its final velocity, even for high-capacity rifles, with slow burning powder. The acceleration is on the order of tens of thousands of gravities, so even a projectile as light as 40 grains (2.6 g), can provide hundreds of pounds-force (over 1000 newtons) of resistance, due to inertia. Changes in bullet mass, therefore, have a huge impact on the pressure curves of smokeless powder cartridges, unlike black powder cartridges. The loading or reloading of smokeless cartridges thus requires high-precision equipment, and carefully-measured tables of load data for given cartridges, powders, and bullet weights.

Pressure

Energy is imparted to the bullet in a firearm by the pressure of the gases produced by the burning gunpowder. While it seems to casual observers that a higher peak pressures should produce higher velocities, that is not always the case, since measures of peak pressure capture only a small fraction of the time the bullet is accelerating. To achieve maximum performance, the entire duration of the bullet's travel through the barrel must be considered.

There are hundreds of powders in existence because powders must be carefully matched to the case volume, case dimensions, bullet dimensions, bullet weight, barrel length, and special bullet features such as moly coating or driving bands. For example, long, heavy bullets are required to be seated so deep in the case that they displace powder, while at the same time requiring a slower powder which gives their greater mass more time to move down the barrel. If the bullet is banded or coated with a lubricant like moly, faster powders can be used as the bullet moves faster due to decreased friction with the barrel. All of these variables must be accommodated within the maximum pressure levels set for the platform. Finding the optimum combination is largely a trial and error process, and may take years to complete. New cartridges with significantly new internal ballistics often bring forth new powders engineered to maximize performance; examples of this are Accurate Arms 2230, designed for use in the .223 Remington, and #9, designed for use in magnum pistol cartridges[1][2].

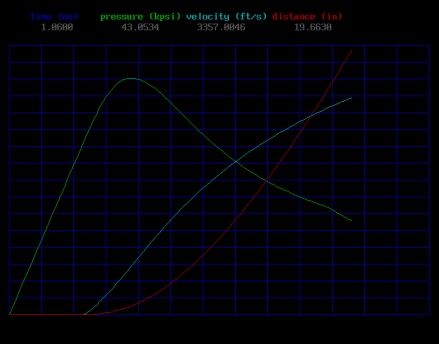

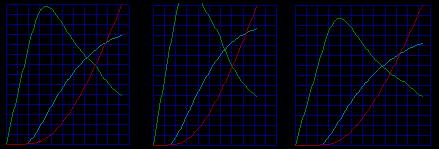

Pressure vs distance traveled

Using powder that is too fast creates a destructive pressure spike that usually has a very short duration. Using powder that is too slow produces poor energy and leaves a lot of unburned powder.

Peak vs area

Energy is defined as a force exerted over a distance; for example, the work required to lift a one-pound weight, one foot against the pull of gravity defines a foot-pound of energy (lifting one newton, one meter gives one newton-meter of energy, called one joule). If we were to modify the graph to reflect pressure as a function of distance, the area under that curve would be the total energy imparted to the bullet. From this, it can be seen that the way to increase the energy of the bullet is to increase the area under that curve, either by raising the average pressure, or increasing the distance, the bullet travels under pressure (in other words, lengthen the barrel).

Propellant burnout

Another issue to consider, when choosing a powder burn rate, is the time the powder takes to completely burn vs. the time the bullet spends in the barrel. Since the burn rate of nitrocellulose-based powders increases with increasing pressure, this can be a very difficult interaction to guess, and requires careful testing with gradual changes. Looking carefully at the left graph, there is a change in the curve, at about 0.8 ms. This is the point at which the powder is completely burned, and no new gas is created. With a faster powder, burnout occurs earlier, and with the slower powder, it occurs later. Propellant that is unburned when the bullet reaches the muzzle is wasted — it adds no energy to the bullet, but it does add to the recoil and muzzle blast. For maximum power, the powder should burn until just short of the muzzle.

Since smokeless powders burn, not detonate, the reaction can only take place on the surface of the powder. Smokeless powders come in a variety of shapes, which serve to determine how fast they burn, and also how the burn rate changes as the powder burns. The simplest shape is a ball powder, which is in the form of round or slightly flattened spheres. Ball powder has a fairly small surface-area-to-volume ratio, so it burns fairly slowly, and as it burns, its surface-area-to-volume ratio decreases. This means as the powder burns, the burn rate slows down.

To some degree, this can be negated by the use of retardant coatings on the surface of the powder, which slows the initial burn rate further, and flattens out the rate of change. Ball powders are generally formulated as slow pistol powders, or fast rifle powders. Flake powders are in the form of flat, round flakes which have a very high surface-area-to-volume ratio. Flake powders have a nearly constant rate of burn, and are usually formulated as fast pistol or shotgun powders. The last common shape is an extruded powder, which is in the form of a cylinder, sometimes hollow. Extruded powders generally have a lower ratio of nitroglycerin to nitrocellulose, and are often progressive burning — that is, they burn at a faster rate as they burn. Extruded powders are generally medium to slow rifle powders.

Muzzle pressure concerns

From the pressure graphs, it can be seen that the residual pressure in the barrel, as the bullet exits, is quite high — in this case, over 16 kpsi / 110000 kPa. / 1100 bar. While lengthening the barrel, or reducing the amount of propellant gas, will reduce this pressure, this is often not possible due to issues of firearm size, and minimum required energy. Short-range target guns are, generally, chambered in .22 Long Rifle, or .22 Short, which have very tiny powder capacities, and little residual pressure. When higher energies are required for long-range shooting, hunting or anti-personnel use, high muzzle pressures are a necessary evil. With this high muzzle pressures come increased flash and noise from the muzzle blast, and due to the large powder charges used, higher recoil — recoil includes the reaction for, not just the bullet, but also for the powder mass.

General concerns

Bore diameter and energy transfer

A firearm, in many ways, is like a piston engine on the power stroke. There is a certain amount of high-pressure gas available, and energy is extracted from it, by making the gas move a piston — in this case, the projectile is the piston. The swept volume of the piston determines how much energy can be extracted from the given gas. The more volume that is swept by the piston, the lower is the exhaust pressure (in this case, the muzzle pressure). Any remaining pressure is lost energy.

To extract the maximum amount of energy, then, the swept volume is maximized. This can be done in one of two ways — increasing the length of the barrel, or increasing the diameter of the projectile. Increasing the barrel length will linearly increase the swept volume, while increasing the diameter will increase the swept volume as the square of the diameter. Since barrel length is limited by practical concerns to about arm's length for a rifle, and much shorter for a handgun, increasing bore diameter is the normal way to increase the efficiency of a cartridge. The limit to bore diameter is generally the sectional density of the projectile (see external ballistics). Larger diameter bullets have much more drag, and so they lose energy very quickly after exiting the barrel. In general, most handguns use bullets between .355 (9 mm) and .45 (11.5 mm) caliber, while most rifles generally range from .223 (5.56 mm) to .32 (8 mm) caliber. There are many exceptions, of course, but bullets in the given ranges provide the best general purpose performance. Handguns use the larger diameter bullets for greater efficiency in short barrels, and tolerate the long-range velocity loss, since handguns are seldom used for long-range shooting. Handguns that are used for long-range shooting are generally closer to shortened rifles than other handguns.

Ratio of propellant to projectile mass

Another issue, when choosing or developing a cartridge, is the issue of recoil. The recoil is not just the reaction from the projectile being launched, but also from the powder gas, which will exit the barrel with a velocity even higher than that of the bullet. For handgun cartridges, with large bullets and small powder charges (a 9x19 mm, for example, might use 5 grains (320 mg) of powder, and a 115 grain (7.5 g) bullet), this is not a significant force; for a rifle cartridge (a .22-250 Remington, using 40 grains (2.6 g) of powder and a 40 grain (2.6 g) bullet), the powder charge can make for the majority of the recoil force.

There is a solution to the recoil issue, though it is not without cost. A muzzle brake or recoil compensator is a device which redirects the powder gas at the muzzle, usually up and back. This acts like a rocket, pushing the muzzle down and forward. The forward push helps negate the feel of the projectile recoil by pulling the firearm forwards. The downward push, on the other hand, helps counteract the rotation imparted by the fact that most firearms have the barrel mounted above the center of gravity. Overt combat guns, large-bore high-powered rifles, long-range handguns chambered for rifle ammunition, and action-shooting handguns designed for accurate rapid fire, all benefit from muzzle brakes.

The high-powered firearms use the muzzle brake mainly for recoil reduction, which reduces the battering of the shooter by the severe recoil. The action-shooting handguns redirect all the energy up to counteract the rotation of the recoil, and make following shots faster by leaving the gun on target. The disadvantage of the muzzle brake is a longer, heavier barrel, and a large increase in sound levels and flash behind the muzzle of the rifle. Shooting firearms without muzzle brakes without hearing protection can eventually damage the operator's hearing. Shooting rifles with muzzle brakes, with or without hearing protection, causes permanent ear damage. (See muzzle brake for more on the disadvantages of muzzle brakes.)

Powder-to-projectile-weight ratio also touches on the subject of efficiency. In the case of the .22-250 Remington, more energy goes into propelling the powder gas than goes into propelling the bullet. The .22-250 pays for this by requiring a large case, with lots of powder, all for a fairly small gain in velocity and energy over other .22 caliber cartridges.

Accuracy and bore characteristics

Nearly all small bore firearms, with the exception of shotguns, have rifled barrels. The rifling imparts a spin on the bullet, which keeps it from tumbling in flight. The rifling is usually in the form of sharp edged grooves cut as helixes along the axis of the bore, anywhere from 2 to 16 in number. The areas between the grooves are known as lands.

Another system, polygonal rifling, gives the bore a polygonal cross section. Polygonal rifling is not very common, used by only a few European manufacturers. The companies that use polygonal rifling claim greater accuracy, lower friction, and less lead and/or copper buildup in the barrel. Traditional land and groove rifling is used in most competition firearms, however, so the advantages of polygonal rifling are unproven.

There are three common ways of rifling a barrel, and one emerging technology:

- The most basic is to use a single point cutter, drawn down the bore by a machine that carefully controls the rotation of the cutting head relative to the barrel. This is the slowest process, but as it requires the simplest equipment, it is often used by custom gunsmiths, and can result in superbly accurate barrels.

- The next method is button rifling. This method uses a die with a negative image of the rifling cut on it. This die is drawn down the barrel while carefully rotated, and it swages the inside of the barrel. This "cuts" all the grooves at once (it does not really cut metal), and so is faster than cut rifling. Detractors claim that the process leaves considerable residual stress in the barrel, but world records have been set with button-rifled barrels, so again there is no clear advantage.

- The last common method used is hammer forging. In this process, a slightly oversized, bored barrel is placed around a mandrel that contains a negative image of the entire length of the rifled barrel. The barrel and mandrel are rotated and hammered by power hammers, which forms the inside of the barrel all at once. This is the fastest (and in the long run, cheapest) method of making a barrel, but the equipment is prohibitively expensive for all but the largest gun makers. Hammer-forged barrels are strictly mass-produced, so they are generally not capable of top accuracy as produced, but with some careful hand work, they can be made to shoot far better than most shooters are capable of.

- A new technique being applied to barrel manufacture is electrical machining, in the form of Electrical discharge machining (EDM) or Electro chemical machining (ECM). These processes use electricity to erode away material, a process produces a highly consistent diameter and very smooth finish, with less stress than other rifling methods. EDM is very costly and primarily used in large bore, long barrel cannon, where traditional methods are very difficult[3], while ECM is used by some smaller barrel makers[4].

The purpose of the barrel is to provide a consistent seal, allowing the bullet to accelerate to a consistent velocity. It must also impart the right spin, and release the bullet consistently, perfectly concentric to the bore. The residual pressure in the bore must be released symmetrically, so that no side of the bullet receives any more or less push than the rest. The muzzle of the barrel is the most critical part, since that is the part that controls the release of the bullet. Some rimfires and airguns actually have a slight constriction, called a choke, in the barrel at the muzzle. This guarantees that the bullet is held securely just before release.

To keep a good seal, the bore must be a very precise, constant diameter, or have a slight decrease in diameter from breech to muzzle. Any increase in bore diameter will allow the bullet to shift. This can cause gas to leak past the bullet, affecting the velocity, or cause the bullet to tip, so that it is no longer perfectly coaxial with the bore. High quality barrels are lapped to remove any constrictions in the bore which will cause a change in diameter.

A lapping process known as "fire lapping" uses a lead "slug" that is slightly larger than the bore and covered in fine abrasive compound to cut out the constrictions. The slug is passed from breech to muzzle, so that as it encounters constrictions, it cuts them away, and does no cutting on areas that are larger than the constriction. Many passes are made, and as the bore becomes more uniform, finer grades of abrasive compound are used. The final result is a barrel that is mirror-smooth, and with a consistent or slightly-tapering bore. The hand-lapping technique uses a wooden or soft metal rod to pull or push the slug through the bore, while the newer fire-lapping technique uses specially-loaded, low-power cartridges to push abrasive-covered soft-lead bullets down the barrel.

Another issue that has an effect on the barrel's hold on the bullet is the rifling. When the bullet is fired, it is forced into the rifling, which cuts or "engraves" the surface of the bullet. If the rifling is a constant twist, then the rifling rides in the grooves engraved in the bullet, and everything is secure and sealed. If the rifling has a decreasing twist, then the changing angle of the rifling in the engraved grooves of the bullet causes the rifling to become narrower than the grooves. This allows gas to blow by, and loosens the hold of the bullet on the barrel. An increasing twist, however, will make the rifling become wider than the grooves in the bullet, maintaining the seal. When a rifled-barrel blank is selected for a gun, careful measurement of the inevitable variations in manufacture can determine if the rifling twist varies, and put the higher-twist end at the muzzle.

The muzzle of the barrel is the last thing to touch the bullet before it goes into ballistic flight, and as such has the greatest potential to disrupt the bullet's flight. The muzzle must allow the gas to escape the barrel symmetrically; any asymmetry will cause an uneven pressure on the base of the bullet, which will disrupt its flight. The muzzle end of the barrel is called the "crown", and it is usually either beveled or recessed to protect it from bumps or scratches that might affect accuracy. A sign of a good crown will be a symmetric, star-shaped pattern on the muzzle end of the barrel, formed by soot deposited, as the powder gases escape the barrel. If the star is uneven, then it is a sign of an uneven crown, and an inaccurate barrel.

Before the barrel can release the bullet in a consistent manner, it must grip the bullet in a consistent manner. The part of the barrel between where the bullet exits the cartridge, and engages the rifling, is called the "throat", and the length of the throat is the "freebore". In some firearms, the freebore is all but nonexistent — the act of chambering the cartridge forces the bullet into the rifling. This is common in low-powered rimfire target rifles. The placement of the bullet in the rifling ensures that the transition between cartridge, and rifling, is quick and stable. The downside is that the cartridge is firmly held in place, and attempting to extract the unfired round can be difficult, to the point of even pulling the bullet from the cartridge in extreme cases.

With high-powered cartridges, there is an additional disadvantage to a short freebore. A significant amount of force is required to engrave the bullet, and this additional resistance can raise the pressure in the chamber by quite a bit. To mitigate this effect, higher-powered rifles tend to have more freebore, so that the bullet is allowed to gain some momentum, and the chamber pressure is allowed to drop slightly, before the bullet engages the rifling. The downside is that the bullet hits the rifling when already moving, and any slight misalignment can cause the bullet to tip, as it engages the rifling. This will, in turn, mean that the bullet does not exit the barrel coaxially. The amount of freebore is a function of both the barrel and the cartridge. The manufacturer or gunsmith who cuts the chamber will determine the amount of space between the cartridge case mouth and the rifling. Setting the bullet further forward or back in the cartridge can decrease or increase the amount of freebore, but only within a small range. Careful testing by the ammunition loader can optimize the amount of freebore to maximize accuracy, while keeping the peak pressure within limits.

See also

- External ballistics

- Percussion cap, for an early history of priming powder and percussion caps

- Terminal ballistics

- Transitional ballistics

References

- ↑ Powder Burnrate Chart

- ↑ http://www.cabelas.com/story-123/boddington_short_mag/10201/The+Short+Mag+Revolution.shtml The Short Mag Revolution

|